M'dziko lomwe likukula mwachangu la kupanga mabatire-kupatsa mphamvu chilichonse kuyambira ma EV mpaka zamagetsi ndi malo osungira magetsi-kuwotcherera kumayimira ngati njira yovuta, koma nthawi zambiri yovuta, yolumikizira batire. Kukhazikika kwa kulumikizana kulikonse kumakhudza mwachindunji chitetezo, magwiridwe antchito, komanso moyo wautali wa paketi. Ku STYLER, timakhazikika pazowotcherera zapamwamba komanso njira zophatikizira zophatikizira paketi, kuphatikiza Precision Resistance.Spot Welders, Makina othamanga kwambiri a Laser Welding, ndi Turnkey Battery Module & Pack Assembly Lines.

We'Talemba mafunso khumi omwe gulu lathu la mainjiniya limakumana nawo pafupipafupi okhudza kuwotcherera mabatire, ndikukupatsani chidziwitso cha akatswiri kuti akuthandizeni kuthana ndi zovuta zake.

1. Ndi njira iti yoyenera kuwotcherera yolumikizira ma cylindrical cell module kapena batri pack busbars?

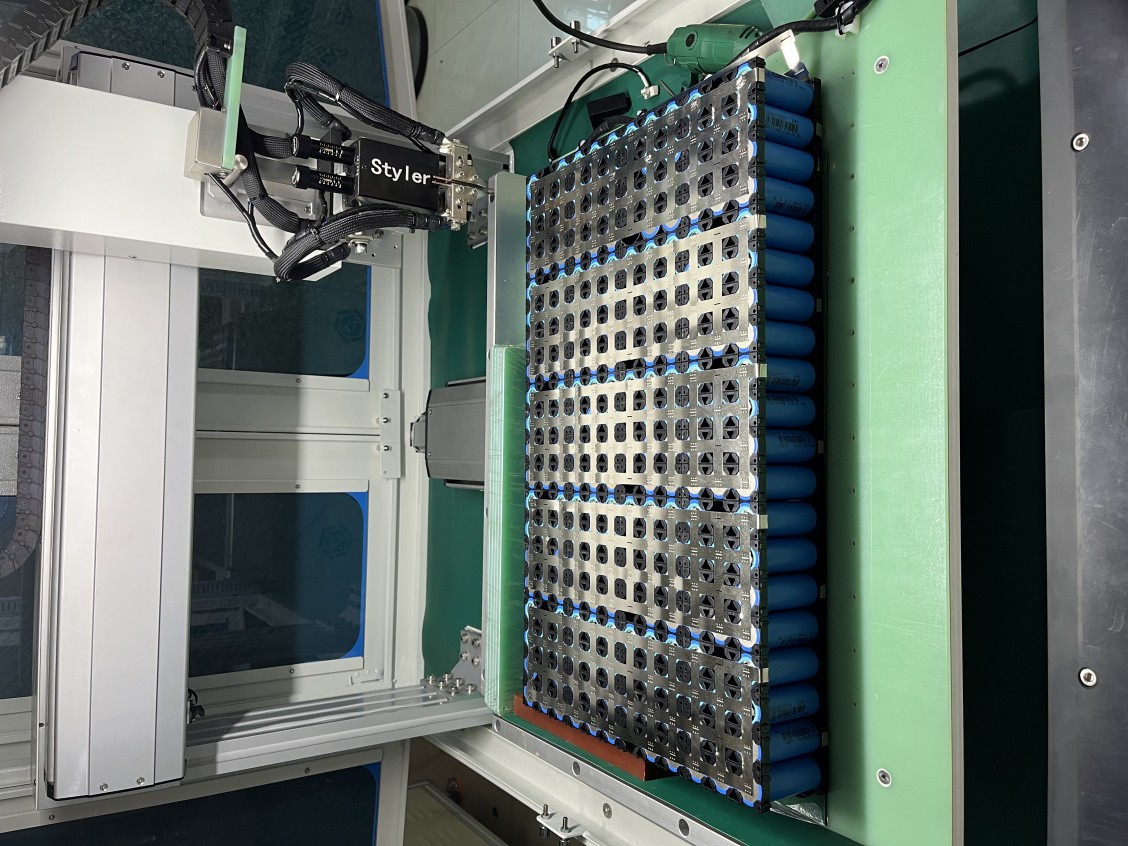

Pakulumikiza maselo kukhala ma module kapena kulumikiza mabasi mkati mwa paketi, Resistance Spot Welding nthawi zambiri ndi chisankho chomwe chimakondedwa.'sa njira yachangu, yotsika mtengo, komanso yodalirika yopangira malumikizano amphamvu amagetsi angapo. Zithunzi za STYLER malo owotcherera, pogwiritsa ntchito ukadaulo wapamwamba wa transistor, imapereka liwiro lapadera ndi kukhazikika, ndi mayankho apano nthawi zonse komanso kuwongolera kosinthika kuti muzitha kunyamula zida zoonda, zowoneka ngati mabasi a faifi tambala.

2. Kodi timapewa bwanji kutenthedwa ndi kuwonongeka kwa kutentha kwa maselo a batri panthawi yowotcherera?

Kusamalira kutentha panthawi yosonkhanitsa katundu ndikofunikira kwambiri. Chofunika kwambiri ndikuwongolera mphamvu zomwe zikubwera mwachangu kwambiri pamalo olumikizirana. Ma Transistor-based Resistance Spot Welders athu amakwaniritsa izi kudzera mu ma welding cycles afupiafupi komanso okhazikika nthawi (milliseconds), kuchepetsa kufalikira kwa kutentha. Pa welding ya laser, kusankha magawo oyenera ndikugwiritsa ntchito ma galvanometer scanners othamanga kwambiri kumalola kutentha komwe kukubwera. Makina athu amatha kuphatikiza kuyang'anira kutentha kuti atsimikizire kuti maselo apafupi amakhalabe mkati mwa malire otetezeka.

3. Aluminium ndi copper-aluminiyamu composites ndizofala mu mabasi apaketi. Kodi njira zowotcherera ndi ziti?

Kuwotcherera zipangizozi kumafuna kusankha mosamala ndondomeko. Pakuwotcherera mawanga, kukhathamira kwa faifi tambala kumafuna kuchuluka kwamphamvu kwakanthawi kochepa. Zowotcherera ma transistor a STYLER zimapereka mphamvu yofunikira mwachangu komanso yokhazikika. Kwa kuwotcherera kwa laser kwamabasi a aluminiyamu ndi zolumikizira, ndizothandiza kwambiri. Komabe, pamabasi amkuwa okha pamisonkhano yapaketi, kuwotcherera kwa laser kumabweretsa zovuta chifukwa chowoneka bwino komanso matenthedwe. Njira yothandiza komanso yovomerezeka ndiyo kugwiritsa ntchito mabasi amkuwa ndi aluminiyamu (zida zovala), pomwe kuwotcherera kwa laser kumapangidwa pazitsulo za aluminiyamu, kuonetsetsa kuti pali mgwirizano wodalirika komanso wokhazikika.

4. Kodi ukhondo wa zinthu zakuthupi ndi kukonzekera pamwamba pa kuwotcherera ndi kofunika bwanji?

Zotsutsa kwambiri. Ma okosijeni, mafuta, ndi zoyipitsidwa pamabasi kapena ma terminals amayambitsa kusagwirizana kwa weld, kuchulukira kwamagetsi, komanso kulephera kwamagetsi. Ntchito yomanga paketi yolimba iyenera kuphatikizapo kuyeretsa koyenera (mwachitsanzo, kuyeretsa ndi laser, kuyeretsa madzi a m'magazi) mwamsanga musanawotchere. STYLER's Battery Pack Assembly Lines imatha kuphatikizira malo oyeretsera makina kuti zitsimikizire kusasinthasintha kwapamtunda pa kulumikizana kulikonse.

5. Kodi timaonetsetsa bwanji kuti weld ali ndi khalidwe labwino pakupanga mapaketi apamwamba kwambiri?

Kusasinthika kumachokera ku kukhazikika kwa zida, kuyang'anira ndondomeko, ndi makina. Makina athu ali ndi:

Kuwunika kwa Nthawi Yeniyeni: Kuyeza kukana kwamphamvu (kuwotchera malo) pa weld iliyonse.

Closed-Loop Adaptive Control: Kusintha ma parameters mokhazikika potengera mayankho.

Kuwunika kwa 100% Post-Weld: Kuphatikiza machitidwe amasomphenya oyika ma weld ndikuyesa kukana kwamagetsi mumzere wa msonkhano kuti atsimikizire mtundu.

6. Kodi ubwino waukulu wa kuwotcherera laser mu batire paketi msonkhano ndi chiyani?

Kuwotcherera kwa Laser kumapereka kusinthasintha kwapadera mu weld geometry (mizere, mabwalo, ma contours), kupsinjika kochepa kwamakina, komanso kuthekera kowotcherera m'mipata yotsekeka mkati mwa paketi. Ndiwoyenera kuwotcherera mbale zomaliza za module, zophimba zophimba (ngati zikuyenera), ndi mawonekedwe ovuta a basi. Zimachepetsa kuvala kwa zida ndikupangitsa kuti seams azithamanga kwambiri, zowoneka bwino.

7. Ndi liti pamene turnkey Battery Pack Assembly Line ndiyofunika vs. standalone welders?

Zowotcherera zoyimirira ndizabwino pa R&D, mizere yoyendetsa, kapena masitepe apadera amsonkhano. A turnkey Battery Pack Assembly Line ndiyofunikira pakuphatikizidwa, kupanga kwamphamvu kwa ma module athunthu kapena mapaketi. STYLER imapanga mizere yomwe imagwiritsa ntchito njira zonse: kuyika ma module, kuyika mabasi, kuwotcherera (malo kapena laser), kuyesa kwamagetsi, ndikuphatikiza komaliza. Izi zimakulitsa kuchulukirachulukira, zimachepetsa zolakwika za anthu, zimawonetsetsa kuti zitha kutsatiridwa, ndikuwongolera malo pansi.

8. Kodi mumalimbana bwanji ndi weld spatter mu batire paketi, zomwe zingayambitse mabwalo afupi?

Spatter mkati mwa paketi ndi chiopsezo chachikulu chachitetezo. Powotcherera pamalo, imayendetsedwa ndikuwongolera mawonekedwe a weld pulse ndi mphamvu ya electrode. Ma Transistor-based Spot Welders amapereka kuwongolera kwamphamvu kwambiri, kumachepetsa kwambiri kutulutsa kwa spatter. Mu kuwotcherera kwa laser, sipatter imachepetsedwa pogwiritsa ntchito mpweya wotchinga wolondola, malo abwino kwambiri, komanso magawo ogwirizana. Makina a STYLER amakonzedwa kuti apange ma welds oyera, ocheperako a spatter omwe amafunikira chitetezo chapaketi.

9. Ndi miyeso iti yomwe tiyenera kugwiritsa ntchito kutsimikizira mtundu wa weld mu paketi?

Kuphatikiza pa kuwunika kowonekera, ma metric otsimikizira ofunikira akuphatikizapo:

Kukaniza kwa Magetsi / Kuwongolera: Kuyesedwa pagulu lililonse la weld; kukana kochepa komanso kosasinthasintha ndikofunikira pakuchita kwa paketi.

Kukoka / Kulimba kwa Peel: Kuyesa kowononga kwamakina pazitsanzo kuwonetsetsa kuti kulumikizana kumakwaniritsa zofunikira.

Kukula kwa Nugget/Kulowa kwa Msoko: Kutsimikiziridwa kudzera mu kusanthula kwa magawo osiyanasiyana panthawi yowunikira njira.

Njira Yolowera Deta: Magawo onse a weld (akali pano, nthawi, mphamvu) amalembedwa ndi zida za STYLER kuti zitheke kupanga.

10. Kodi makampani akusintha bwanji kuwotcherera kwa mapaketi atsopano ngati CTC (Cell-to-Chassis) kapena mapaketi akulu akulu?

Mapangidwewa amafunikira njira zowotcherera zomwe zimapanga zolumikizira zolimba, zodalirika zamagetsi komanso nthawi zina zamapangidwe pamlingo wokulirapo. Amakankhira zofunikira pakuzama kwa weld, liwiro, ndi kusasinthika. Ma High-Power Laser Welders amagwiritsidwa ntchito mochulukira pakuwotcherera kwa msoko wautali pamapaketi am'mapaketi ndi mabasi omangidwa. STYLER ili patsogolo, ikupanga mayankho ndi mphamvu yofunikira, kulondola, komanso kulimba mtima kuti akwaniritse zovuta zapaketi zam'badwo wotsatirazi.

Mapeto

Battery pack welding ndi njira yolondola yomwe imayang'ana pakupanga malumikizano abwino amagetsi mkati mwa msonkhano wotetezeka komanso wodalirika. Chiyanjano choyenera ndi chisankho chaukadaulo ndizosankha kuti chinthu chanu chichite bwino.

Ku STYLER, timapereka mayankho olunjika pakuphatikiza mapaketi a batri. Kuchokera pa kukhazikika kwachangu kwa Transistor-based Resistance Spot Welders ndi kusinthasintha kosinthika kwa Laser Welding Systems yathu mpaka makina ophatikizika a Battery Pack Assembly Lines athu, tadzipereka kupatsa mphamvu kupanga kwanu modalirika, mwaluso, komanso kuchita bwino.

Kodi mwakonzeka kukhathamiritsa njira yowotcherera ya batri yanu? Lumikizanani ndi akatswiri a STYLER lero kuti mukambirane.

Nthawi yotumiza: Dec-11-2025