Zogulitsa

Automatic Lithium Battery Ev Battery Pack Assembly Line Yosungira Mphamvu

UBWINO WA MATUPI AMAWAYA OVUNUKA

1, Kutengera mawonekedwe osinthika a quide njanji

2, Kukhathamiritsa njira kudzera mwa kuphatikiza makina a anthu kuti muwongolere bwino

3. Single makina ntchito pawokha

4, Kugwiritsa ntchito kalozera njanji RFID zoyendera ndi kulemba deta siteshoni

5, Kuphatikiza kosasinthika kwa mawonekedwe a makina a anthu,ndi makina-anthu amathanso kusinthanitsa pa nthawi ya anv

6, The PACK ndondomeko akhoza kusinthidwa ndipo akhoza kuikidwa inproduction pambuyo docking

7, Deta yopangira ikhoza kukwezedwa munthawi yake.ndipo zogwirira ntchito zimamveka bwino

Parameter

| Kusanja kugunda | 0.6s/pc |

| Kuyerekeza kwamphamvu | 4000pcs/h |

| Zida zamagetsi | 220V 50HZ |

| Zida mpweya kuthamanga | 0.4 ~ 0.6Mpa (Mpweya wouma komanso wosasunthika) |

| Malo opangira mzere | Malo opangira mzere |

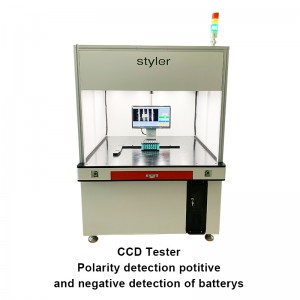

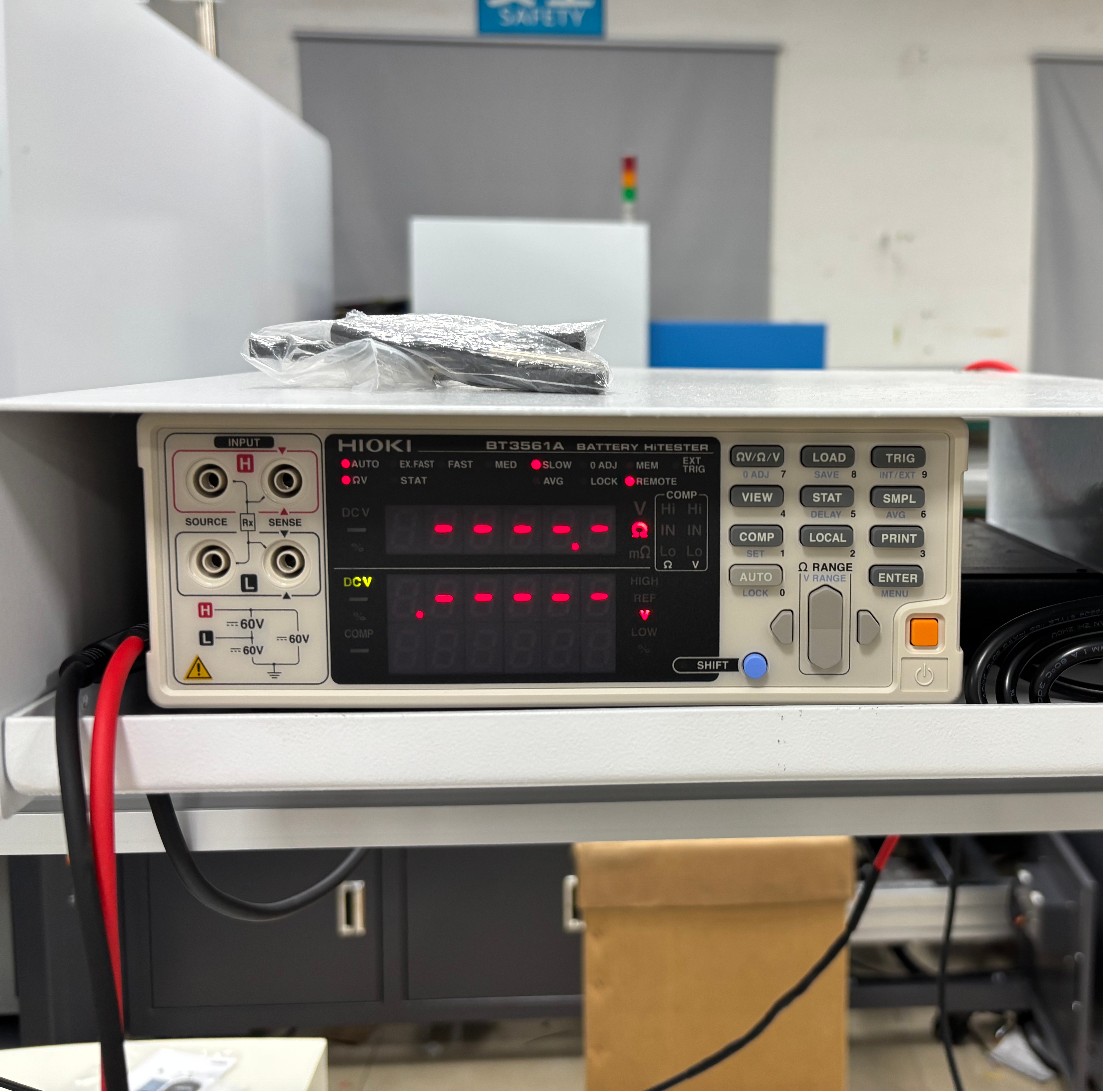

Zosankha zowonjezera

Barcode Scanner: Kusanthula kuti musankhe pulogalamu yowotcherera, kuwotcherera basi

Internal Resistance Tester: Kuyang'ana pambuyo-weld kukana kwamkati kwa paketi

Kugwiritsa Ntchito Battery Pack

Lithium batire paketi chimagwiritsidwa ntchito kwambiri msika ogula zamagetsi, kuphimba mafoni, Malaputopu, makamera digito, kunyamula

zipangizo, magalimoto amagetsi, kuwala kwa dzuwa ndi zina zotero. Lithium batire paketi ndondomeko amatanthauza msonkhano wa batire, BMS, batire

waya, ntchentche za faifi tambala, zida zothandizira, chosungira ma cell etc mu batire yomalizidwa ndi kuwotcherera. M'munda wa ogula

zamagetsi, ukadaulo ndi msika wa batire paketi ndizokhwima, zomwe zikukula.

Makhalidwe a Battery Pack

① Battery Pack imafuna kusasinthika kwakukulu kwa batri (kuthekera, kukana kwamkati, voliyumu, piritsi lotulutsa, moyo).

② Moyo wozungulira wa paketi ndi wotsika kuposa wa batri limodzi.

③ Gwiritsani ntchito mochepera (kuphatikiza kulipiritsa, kutulutsa pakali pano, kuyitanitsa, kutentha, ndi zina).

④ Pambuyo popanga paketi, mphamvu yamagetsi ndi mphamvu ya batire ya lithiamu yasinthidwa bwino, chifukwa chake iyenera kutetezedwa, ndikuyesa kufanana, kutentha, magetsi ndi kuwunika kwakanthawi kopitilira muyeso kuyenera kuchitika.

⑤ Paketi ya batri iyenera kukwaniritsa mphamvu zamagetsi ndi mphamvu zomwe zimapangidwa.

Chidziwitso Chodziwika cha Sayansi

Lithium batire paketi chimagwiritsidwa ntchito kwambiri msika ogula zamagetsi, kuphimba mafoni, Malaputopu, makamera digito, kunyamula

zipangizo, magalimoto amagetsi, kuwala kwa dzuwa ndi zina zotero. Lithium batire paketi ndondomeko amatanthauza msonkhano wa batire, BMS, batire

waya, ntchentche za faifi tambala, zida zothandizira, chosungira ma cell etc mu batire yomalizidwa ndi kuwotcherera. M'munda wa ogula

zamagetsi, ukadaulo ndi msika wa batire paketi ndizokhwima, zomwe zikukula.

① Battery Pack imafuna kusasinthika kwakukulu kwa batri (kuthekera, kukana kwamkati, voliyumu, piritsi lotulutsa, moyo).

② Moyo wozungulira wa paketi ndi wotsika kuposa wa batri limodzi.

③ Gwiritsani ntchito mochepera (kuphatikiza kulipiritsa, kutulutsa pakali pano, kuyitanitsa, kutentha, ndi zina).

④ Pambuyo popanga paketi, mphamvu yamagetsi ndi mphamvu ya batire ya lithiamu yasinthidwa bwino, chifukwa chake iyenera kutetezedwa, ndikuyesa kufanana, kutentha, magetsi ndi kuwunika kwakanthawi kopitilira muyeso kuyenera kuchitika.

⑤ Paketi ya batri iyenera kukwaniritsa mphamvu zamagetsi ndi mphamvu zomwe zimapangidwa.

Timakhala ku Guangdong, China, kuyambira 2010, kugulitsa ku Msika Wapakhomo (50.00%), North America (15.00%), South America (5.00%), Eastern Europe (5.00%), Western Europe (5.00%), Southeast Asia (3.00%), Oceania (3.00%), 0Mid. Kummawa(2.00%),Central America(2.00%),Northern Europe(2.00%),Southern Europe(2.00%). Pali anthu pafupifupi 51-100 muofesi yathu.

Nthawi zonse chisanadze kupanga chisanadze kupanga misa; Nthawi zonse Kuyendera komaliza musanatumize;

Lithium Battery Assembly Automation Line,Battery Spot Welding Machine,Battery Sorting Machine,Battery Comprehensive Tester System,Battery Aging Cabinet

Tili ndi amphamvu luso R & D gulu ndipo takhala tikugwira ntchito mu lifiyamu batire msonkhano ndi kupanga makampani kwa zaka zambiri ndi zinachitikira wolemera. Kampaniyo tsopano ili ndi mitundu yosiyanasiyana komanso mitundu yamakina ndi zida, mndandanda wosiyanasiyana

Malamulo Ovomerezeka Ovomerezeka: FOB, EXW; Ndalama Zolipira: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF; Mtundu wa Malipiro Ovomerezeka: T/T,L/C,D/PD/A,PayPal; Chiyankhulo cholankhulidwa: Chingerezi, Chitchaina